Clear float glass is produced with a mixture of silicon sand, natural ores and chemical materials molten at high temperatures. The molten glass flows to the tin bath, spread under the works of gravity and surface becomes smooth and flat at both sides.

On-line reflective is a solar control glass that adopts CVD technology (chemical vapor deposition) by creating a perfect uniform layer of metal oxide chemically bonded to the surface of glass. The coating brings a mirror effect to the facade and enhances its functional benefits in solar control and glare reduction. This evolved glass products perfectly meet the requirements of architecture both in function and aesthetics.

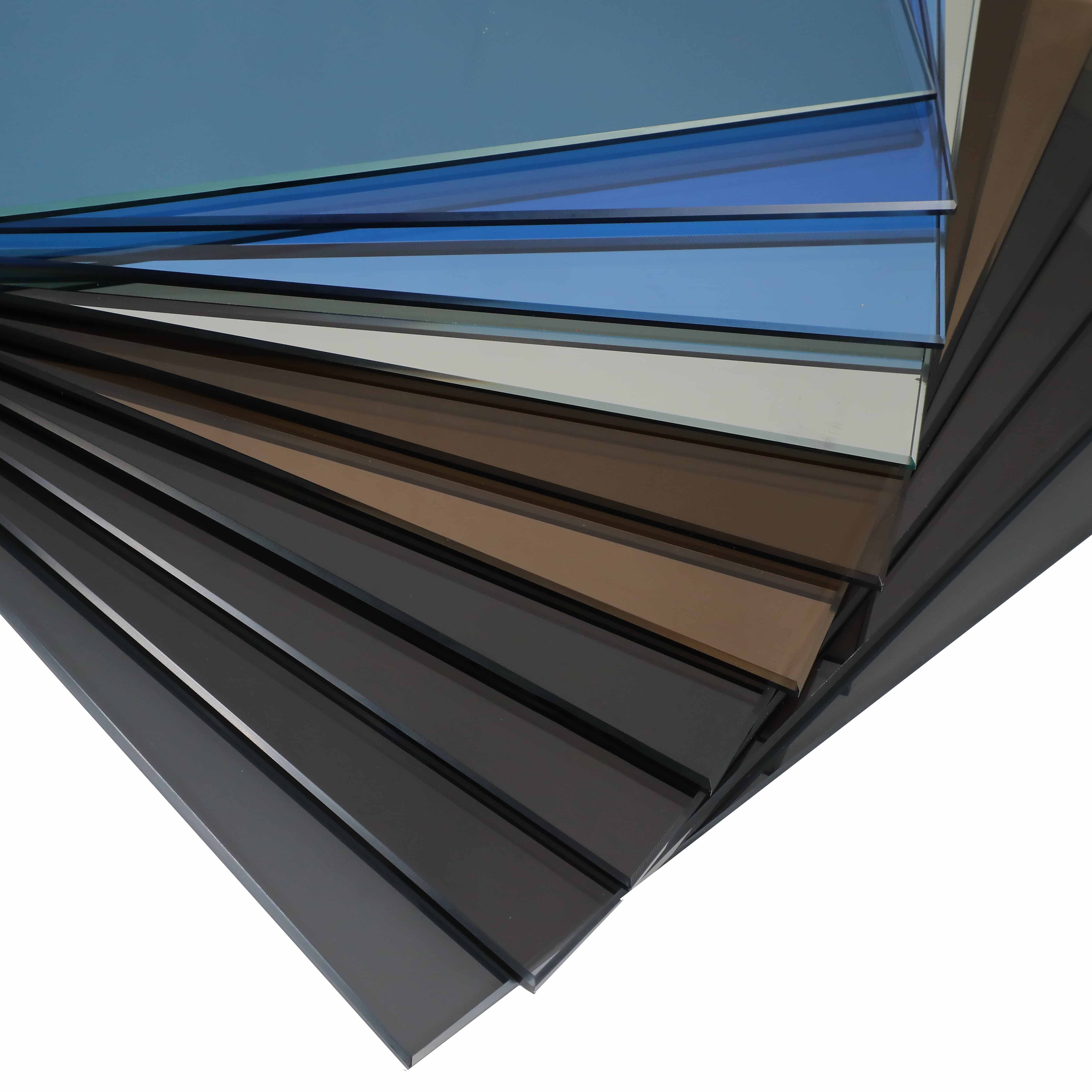

Body Tinted glass is produced under the float process with the addition of a moderate quantity of metal oxides at the molten stage which colored the normal clear glass and thus achieve glass color diversities. The coloration does not affect the basic property of glass. Visible light transmittance decreases accompanied with the thickness increase. Tinted glass with good performance in reducing solar transmittance by absorbing a large proportion of solar energy, the majority of which is dissipated outside by re-radia-tion and convection.

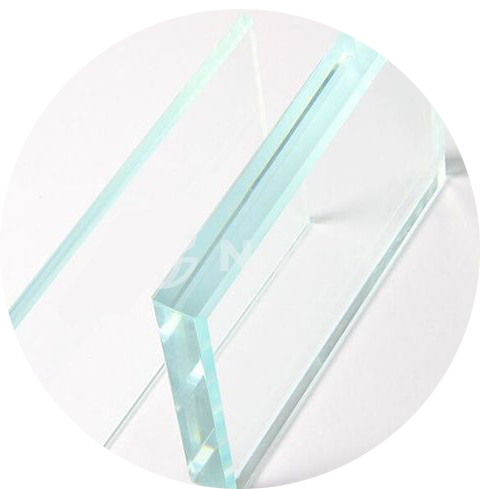

Ultra clear glass also named Low-iron glass with distinguishing feature of super white, excellent color consistency and high transparency which light transmittance is over 91.5%. It is deeply processed with a series of physical and chemical working procedure to remove iron impurity from normal clear glass and achieves crystalline lucency. It is a new type, multifunctional and high-end quality glass product which is widely applied in environmental protection and energy saving.